Innovative Tools and Machines That Will Revolutionize Your Work

By:Admin

In the world of engineering and manufacturing, having the right tools and machines can make all the difference. That’s why [Engineering Company] is proud to introduce a new line of innovative and high-quality tools and machines designed to streamline production processes and increase efficiency.

Founded in [year], [Engineering Company] has been a leader in providing engineering solutions for a wide range of industries. With a focus on innovation and continuous improvement, the company has consistently developed cutting-edge technologies and products to meet the ever-evolving needs of its clients.

The latest offering from [Engineering Company] includes a range of tools and machines that are designed to revolutionize the way manufacturing processes are conducted. These products have been meticulously engineered to meet the highest standards of quality and performance, and are backed by the company’s commitment to excellence.

One of the standout products in this new line is the [Tool/Machine], which is designed to [brief description of the product and its functions]. This innovative tool has been developed using the latest technology and engineering principles, resulting in a product that is not only highly efficient, but also durable and reliable.

In addition to the [Tool/Machine], [Engineering Company] is also introducing several other new products, including [Tool/Machine], [Tool/Machine], and [Tool/Machine]. Each of these products has been carefully crafted to address specific needs within the engineering and manufacturing industries, and showcases the company’s dedication to providing comprehensive solutions for its clients.

What sets [Engineering Company] apart from its competitors is its unwavering commitment to customer satisfaction. The company understands that each client has unique requirements and challenges, and strives to provide personalized solutions that address these specific needs. With the introduction of these new tools and machines, [Engineering Company] is further solidifying its position as a leading provider of engineering solutions.

“We are truly excited to introduce our latest line of tools and machines to the market,” said [Spokesperson], [Title] at [Engineering Company]. “These products are the result of extensive research and development, and we believe they have the potential to significantly enhance manufacturing processes for our clients. We are confident that these tools and machines will make a positive impact, and we look forward to seeing the difference they can make for businesses across a range of industries.”

With a focus on innovation, quality, and customer satisfaction, [Engineering Company] is well-positioned to continue leading the way in the engineering and manufacturing industries. The company’s latest offering of tools and machines is a testament to its ongoing commitment to providing state-of-the-art solutions for its clients, and is poised to make a significant impact in the industry.

As [Engineering Company] continues to grow and evolve, one thing remains constant – its dedication to excellence. The introduction of these new tools and machines is just the latest example of the company’s commitment to pushing the boundaries of what is possible in engineering and manufacturing, and its relentless pursuit of providing the best solutions for its clients.

For more information about [Engineering Company] and its new line of tools and machines, please visit [company website] or contact [contact information] for inquiries.

Company News & Blog

Top benefits of laser sheet cutting for precision and efficiency

Laser Sheet Cutting Technology Revolutionizing Manufacturing IndustryIn today's fast-paced world, technological advancements continue to drive innovation and change the landscape of various industries. The manufacturing sector, in particular, has seen tremendous growth and transformation, thanks to cutting-edge technologies such as Laser Sheet Cutting. This innovative process has revolutionized the manufacturing industry, enabling companies to achieve higher levels of precision, efficiency, and cost-effectiveness in their production processes.Laser Sheet Cutting, also known as laser cutting, is a method of manufacturing that uses a high-powered laser to cut materials with precision and accuracy. The process involves directing the laser beam onto the material, which then melts, burns, or vaporizes away, leaving a high-quality finish. This technology is widely used in various industries, including automotive, aerospace, electronics, and defense, to produce intricate and complex parts with unparalleled precision.One of the leading providers of Laser Sheet Cutting solutions is [Company Name], a renowned company specializing in advanced manufacturing technologies. With a strong focus on innovation and quality, [Company Name] has established itself as a trusted partner for businesses looking to enhance their production capabilities. The company's state-of-the-art facilities and experienced team of experts have enabled them to deliver cutting-edge solutions to their clients, meeting the highest standards of quality and precision.[Company Name] offers a wide range of Laser Sheet Cutting services, including 2D and 3D cutting, tube cutting, and robotic cutting, catering to the diverse needs of their clients. Their advanced machinery and sophisticated software ensure that they can handle complex projects with ease, delivering outstanding results within tight tolerances. Additionally, their commitment to continuous improvement and investment in the latest technologies has positioned them as a leader in the industry, driving the advancement of Laser Sheet Cutting capabilities.The benefits of Laser Sheet Cutting are far-reaching, providing manufacturers with a competitive edge in today's market. The technology offers unparalleled accuracy, allowing for the production of intricate and complex designs with minimal error. Moreover, Laser Sheet Cutting is a versatile process that can be used on a wide range of materials, including metal, plastic, wood, and ceramics, making it suitable for a variety of applications. This versatility enables manufacturers to explore new possibilities and push the boundaries of what is achievable in their production processes.Furthermore, Laser Sheet Cutting is a highly efficient process, reducing material waste and optimizing production times. The precision of the laser guarantees clean and smooth cuts, minimizing the need for post-processing and finishing, ultimately saving time and costs for manufacturers. Additionally, the non-contact nature of the laser cutting process reduces the risk of material contamination, ensuring the highest levels of quality and integrity in the final product.With the demand for high-quality, precision-engineered components growing across various industries, Laser Sheet Cutting has become an indispensable tool for manufacturers striving to meet these needs. As the technology continues to evolve and improve, companies like [Company Name] are at the forefront, driving innovation and pushing the boundaries of what is possible in manufacturing.In conclusion, Laser Sheet Cutting technology has revolutionized the manufacturing industry, offering unprecedented precision, efficiency, and versatility for manufacturers. As technology continues to evolve, companies like [Company Name] are leading the charge, providing cutting-edge solutions to meet the growing demands of today's market. With their commitment to innovation and quality, [Company Name] is poised to continue shaping the future of manufacturing with Laser Sheet Cutting technology.

High-Quality Industrial Metal Cutting Drills and Saws with CNC Precision for Structural Steel Industry

and Industrial Metal Cutting Drills & Saws for best optimization.Industrial metal cutting drills & saws are essential to many industries, particularly structural steel. Cutting through metal is no easy feat, but with the right equipment, it can be done with ease and precision.That is where Peerless Industrial Equipment comes in. With a long and proud tradition of providing the finest industrial metal cutting drills & saws, Peerless is a go-to source for industrial metal cutting needs. But now, they have taken their offerings to the next level with the addition of Daito CNC products for the structural steel industry.What makes Peerless Industrial Equipment stand out from the competition is their commitment to quality and precision. Their cutting tools are designed with superior materials and craftsmanship to ensure that every cut is precise and accurate. Whether you are working on a small project or a large-scale one, Peerless has the tools to help you get the job done right.One of Peerless's most popular products is their CNC drive motors. These motors are designed to provide the power and precision needed for industrial metal cutting drills & saws. With a range of sizes and powers available, you can find the perfect motor for your needs.In addition to their CNC drive motors, Peerless also offers a wide range of industrial metal cutting drills & saws. Their products include everything from band saws and circular saws to drill presses and more. No matter your cutting needs, Peerless has the tools to help you get the job done.So why choose Peerless Industrial Equipment? The answer is simple: quality, precision, and customer service. Peerless is committed to providing the finest industrial metal cutting drills & saws on the market, and they back up their products with exceptional customer service. Whether you need help finding the right tool for your needs or have a question about one of their products, their team is always there to help.In conclusion, if you are in need of industrial metal cutting drills & saws, look no further than Peerless Industrial Equipment. With their superior products, exceptional customer service, and commitment to quality and precision, they are the go-to source for all your cutting needs. And with the addition of Daito CNC products for the structural steel industry, they are more than ready to take on any challenge you might have. So why wait? Contact Peerless today and see how they can help you get the job done right.

How Laser Cleaning Machines are Revolutionizing Industrial Cleaning Technology

Introducing Fiber Laser Cleaning Machine: Revolutionizing Industrial Cleaning Processes[Company Introduction]In today's rapidly evolving industrial landscape, the need for efficient and environmentally friendly cleaning processes has become more vital than ever. Recognizing this demand, {Company Name}, a global leader in advanced manufacturing solutions, proudly presents its latest innovation – the Fiber Laser Cleaning Machine. This cutting-edge technology aims to revolutionize industrial cleaning by providing a highly effective, precise, and eco-friendly solution for various industries.[Overview of Fiber Laser Cleaning Machine]The Fiber Laser Cleaning Machine is a state-of-the-art equipment designed to remove contaminants, rust, and unwanted coatings from the surfaces of various materials, including metal, plastic, and stone. Utilizing high-intensity laser beams, this innovative cleaning system offers a non-contact and non-abrasive approach to industrial cleaning, ensuring the preservation of delicate surfaces and eliminating the need for costly and potentially damaging chemical agents.[Features and Benefits]1. Superior Cleaning Performance: The Fiber Laser Cleaning Machine employs a high-power laser beam, which generates a powerful and focused energy that effectively disintegrates and vaporizes contaminants. This process ensures that even the most stubborn residues, such as grease, rust, or paint, are thoroughly removed, leaving behind a pristine surface.2. Precision and Versatility: With advanced scanning technology, users have the flexibility to tailor the cleaning patterns and intensity according to their specific requirements. Whether it's cleaning intricate machinery parts, large-scale industrial equipment, or historical artifacts, the Fiber Laser Cleaning Machine offers unparalleled precision and adaptability.3. Environmentally Friendly Solution: In a world increasingly focused on sustainability, the Fiber Laser Cleaning Machine sets new standards for eco-friendly cleaning solutions. By eliminating the need for harsh chemicals or solvents, this innovative system significantly reduces waste generation and eliminates harmful emissions, ensuring a safer working environment for employees and reducing environmental impact.4. Cost-effective and Time-efficient: The Fiber Laser Cleaning Machine is a cost-effective alternative to traditional cleaning methods. With its high cleaning speed and efficiency, it minimizes downtime, maximizing productivity, and reducing labor costs. Additionally, its non-abrasive nature, which eliminates the risk of surface damage, reduces the need for costly repairs and replacements.5. Enhanced Safety: The Fiber Laser Cleaning Machine prioritizes the safety of its users. Equipped with protective shields and safety features, it minimizes the risk of accidents and injuries, ensuring operators can work confidently and securely. Furthermore, the laser system's non-toxic and non-contact cleaning mechanism provides a safer working environment for employees.[Applications]The Fiber Laser Cleaning Machine finds extensive applications across various industries, including:1. Automotive: Removing rust, paint, and coatings from car bodies, parts, and engine components.2. Aerospace: Cleaning critical components, such as turbine blades, without damaging their delicate surfaces.3. Manufacturing: Eliminating contaminants from tools, molds, and machinery parts, ensuring optimal performance and prolonging their lifespan.4. Restoration: Safely restoring historical artifacts, sculptures, and antiques without causing any irreversible damage.5. Electronics: Cleaning delicate electronic circuits, PCBs, and components without the need for chemicals or solvents.[Future Prospects]As industries continue to seek efficient and sustainable cleaning solutions, the Fiber Laser Cleaning Machine presents a promising future. Its advanced capabilities not only enhance cleaning processes but also contribute to increased productivity, reduced costs, and a safer working environment for employees. With continuous research and development, {Company Name} is committed to pushing the boundaries of innovation, fostering industrial growth, and addressing the evolving needs of its clients.In conclusion, the introduction of the Fiber Laser Cleaning Machine marks a significant milestone in the field of industrial cleaning. Its ability to combine cutting-edge technology, environmental consciousness, precision, and cost-effectiveness sets it apart from traditional cleaning methods. With {Company Name}'s dedication to advancing manufacturing solutions, the Fiber Laser Cleaning Machine is poised to reshape industrial cleaning practices, optimize efficiency, and pave the way for a cleaner and more sustainable future.

Cost-Effective and Reliable Laser Cleaning Solution with In-Line Process Control for Industrial Use

Laser cleaning is cost-effective and reliable, making it an attractive solution for a range of industries and applications. From aerospace and automotive to medical device manufacturing and electronics, laser cleaning offers a non-destructive, precise, and eco-friendly way to remove contaminants, coatings, oxides, and other unwanted substances from surfaces.One of the latest developments in laser cleaning technology is the integration of process monitoring and in-line process control. This allows for real-time feedback and adjustment of laser parameters, ensuring consistent and optimal cleaning results. One company that has pioneered this approach is (brand name), a leading provider of laser cleaning systems."We believe that laser cleaning is the future of industrial cleaning," says (spokesperson). "Our systems offer a level of precision, efficiency, and safety that traditional methods simply can't match. With the addition of process monitoring and control, our customers can further improve their productivity, quality, and cost-effectiveness."So, how does laser cleaning work? Essentially, a high-intensity laser beam is focused on the surface to be cleaned, causing the contaminants to evaporate or ablate. The laser light is directed with precision using mirrors, lenses, and scanners, allowing for selective cleaning of specific areas or shapes. Unlike mechanical or chemical treatments, laser cleaning does not cause any physical or chemical damage to the substrate, and does not generate any waste or residue to dispose of.Laser cleaning can be used on a wide range of materials, including metals, ceramics, plastics, glass, and composites. It can remove rust, paint, grease, adhesives, carbon, oxides, mold release agents, and other contaminants. Laser cleaning can also be used to prepare surfaces for subsequent treatments such as bonding, welding, painting, or coating.One of the key advantages of laser cleaning is its cost-effectiveness. While the initial investment in a laser cleaning system may seem high compared to traditional methods, the long-term benefits can outweigh the costs. Laser cleaning does not require any consumables such as abrasive media, chemicals, or brushes, which can add up over time. Laser cleaning is also faster than most other methods, which means less downtime and increased throughput. Moreover, laser cleaning can reduce the need for expensive manual labor, as it can be automated and integrated into production lines.Another advantage of laser cleaning is its reliability. Laser cleaning systems are designed for industrial use and can withstand harsh environments and high volumes of cleaning. They are also easy to maintain and have a long lifespan, which reduces the need for frequent replacements or repairs. Laser cleaning systems can also be customized to meet specific customer needs, such as size, power, wavelength, and automation.In addition to cost-effectiveness and reliability, laser cleaning also offers environmental benefits. Laser cleaning does not generate any hazardous waste, air emissions, or water pollution, making it a sustainable option for companies that value environmental stewardship. Laser cleaning also reduces the use of chemicals and other hazardous materials, which can improve workplace safety and reduce regulatory compliance costs.As laser cleaning technology continues to evolve and improve, its applications are likely to expand as well. Already, laser cleaning is being used in industries such as aerospace, automotive, medical devices, electronics, and cultural heritage preservation. Laser cleaning is also being explored for applications such as graffiti removal, corrosion prevention, and even food processing.Overall, laser cleaning is a cost-effective and reliable solution for industrial cleaning that offers a range of benefits compared to traditional methods. As companies seek to improve their efficiency, quality, and sustainability, laser cleaning is likely to play an increasingly important role in their operations.

Innovative Tools and Machines That Will Revolutionize Your Work

Engineering Company Introduces Innovative Tools and MachinesIn the world of engineering and manufacturing, having the right tools and machines can make all the difference. That’s why [Engineering Company] is proud to introduce a new line of innovative and high-quality tools and machines designed to streamline production processes and increase efficiency.Founded in [year], [Engineering Company] has been a leader in providing engineering solutions for a wide range of industries. With a focus on innovation and continuous improvement, the company has consistently developed cutting-edge technologies and products to meet the ever-evolving needs of its clients.The latest offering from [Engineering Company] includes a range of tools and machines that are designed to revolutionize the way manufacturing processes are conducted. These products have been meticulously engineered to meet the highest standards of quality and performance, and are backed by the company’s commitment to excellence.One of the standout products in this new line is the [Tool/Machine], which is designed to [brief description of the product and its functions]. This innovative tool has been developed using the latest technology and engineering principles, resulting in a product that is not only highly efficient, but also durable and reliable.In addition to the [Tool/Machine], [Engineering Company] is also introducing several other new products, including [Tool/Machine], [Tool/Machine], and [Tool/Machine]. Each of these products has been carefully crafted to address specific needs within the engineering and manufacturing industries, and showcases the company’s dedication to providing comprehensive solutions for its clients.What sets [Engineering Company] apart from its competitors is its unwavering commitment to customer satisfaction. The company understands that each client has unique requirements and challenges, and strives to provide personalized solutions that address these specific needs. With the introduction of these new tools and machines, [Engineering Company] is further solidifying its position as a leading provider of engineering solutions.“We are truly excited to introduce our latest line of tools and machines to the market,” said [Spokesperson], [Title] at [Engineering Company]. “These products are the result of extensive research and development, and we believe they have the potential to significantly enhance manufacturing processes for our clients. We are confident that these tools and machines will make a positive impact, and we look forward to seeing the difference they can make for businesses across a range of industries.”With a focus on innovation, quality, and customer satisfaction, [Engineering Company] is well-positioned to continue leading the way in the engineering and manufacturing industries. The company’s latest offering of tools and machines is a testament to its ongoing commitment to providing state-of-the-art solutions for its clients, and is poised to make a significant impact in the industry.As [Engineering Company] continues to grow and evolve, one thing remains constant – its dedication to excellence. The introduction of these new tools and machines is just the latest example of the company’s commitment to pushing the boundaries of what is possible in engineering and manufacturing, and its relentless pursuit of providing the best solutions for its clients.For more information about [Engineering Company] and its new line of tools and machines, please visit [company website] or contact [contact information] for inquiries.

The Benefits of Laser Slitting Technology for Industrial Applications

Laser Slitting is a cutting-edge technology that has revolutionized the manufacturing industry by offering precise and efficient cutting solutions for various materials including paper, plastic, metal, and more. By using a high-powered laser beam, Laser Slitting can quickly and accurately cut through materials with an unprecedented level of precision, making it an ideal choice for companies looking to optimize their production processes. One company that has fully embraced the potential of Laser Slitting is {}, a leader in the field of precision manufacturing.{} is a renowned manufacturer known for its commitment to innovation and excellence. With state-of-the-art facilities and a team of experienced professionals, the company has been at the forefront of the industry, delivering high-quality products and services to a wide range of clients. By leveraging the latest technologies, including Laser Slitting, {}, has been able to stay ahead of the competition and meet the evolving needs of its customers.Laser Slitting has several key advantages that make it a preferred choice for companies in various industries. One of the main benefits of Laser Slitting is its ability to provide precise and clean cuts, which is crucial for industries that require high levels of accuracy. Unlike traditional mechanical cutting methods, Laser Slitting does not involve any physical contact with the material, resulting in minimal wear and tear and ensuring consistent quality. This is particularly important for companies like {}, which prioritize precision and reliability in their manufacturing processes.In addition to its precision, Laser Slitting also offers significant flexibility, allowing companies to cut a wide range of materials with ease. Whether it's thin films, thick plastics, or metal sheets, Laser Slitting can handle it all, making it a versatile solution for companies with diverse material cutting needs. This level of adaptability is a key factor in why {} has chosen to integrate Laser Slitting into its operations, enabling the company to meet the demands of its clients across different industries.Furthermore, Laser Slitting has proven to be highly efficient, contributing to increased productivity and cost savings. By automating the cutting process and eliminating the need for manual adjustments, Laser Slitting enables companies to streamline their operations and reduce production time. This efficiency is particularly valuable for companies like {}, which are constantly looking for ways to improve their manufacturing processes and deliver superior results to their customers.As a forward-thinking company, {} understands the importance of investing in cutting-edge technologies like Laser Slitting to stay competitive in the market. By embracing this innovative approach to manufacturing, {} has been able to enhance its capabilities and offer even greater value to its clients. With Laser Slitting, the company is well-equipped to take on complex cutting challenges and deliver exceptional results with precision and efficiency.In conclusion, Laser Slitting has revolutionized the manufacturing industry by offering a superior cutting solution that is precise, flexible, and efficient. {} is a prime example of a company that has fully utilized the potential of Laser Slitting to elevate its manufacturing capabilities and deliver exceptional products and services to its clients. As the industry continues to evolve, Laser Slitting will undoubtedly play a pivotal role in driving innovation and shaping the future of manufacturing. With its commitment to innovation and excellence, {} is well-positioned to continue leveraging the power of Laser Slitting and maintain its leadership in the industry.

Revolutionizing Welding Technology: Discover the Power of Portable Laser Welding Machines

Portable Laser Welding Machine: The Revolutionary Solution for Welding NeedsWelding has been an essential part of manufacturing and construction industries for decades. However, traditional welding methods require a substantial amount of time, cost, and effort, which can be inefficient and laborious. With the advancements in technology, the Portable Laser Welding Machine has emerged as a game-changer in the world of welding.This revolutionary invention has the potential to improve the efficiency, accuracy and precision of welding processes, as well as offer cost-effective solutions in various industries. The Portable Laser Welding Machine is a highly precise and innovative tool that uses a concentrated beam of laser light to weld metal together. This machine is a small, lightweight and portable device that can easily be carried to different locations.What sets the Portable Laser Welding Machine apart from conventional welding methods is its incredibly fast and efficient nature. The laser beam is capable of penetrating the metal and creating a deep weld in just a matter of seconds. The precision of the machine ensures that there is minimal splattering and distortion, making it an ideal choice for applications that require clean and accurate welds.With its innovative design, the Portable Laser Welding Machine offers several advantages over traditional welding methods. Unlike conventional welding techniques, laser welding does not require any filler material, which drastically reduces the cost and time spent on welding. The machine can weld a wide range of metals, including stainless steel, aluminum, and titanium, making it a versatile tool for a variety of industries.The Portable Laser Welding Machine is also highly efficient and requires minimal maintenance. Unlike traditional welding equipment, this device does not require any gas supply or compressed air, which significantly reduces the cost of operation and eliminates the risk of gas leaks. The machine is also self-contained and can be operated by a single person, which saves time and labor costs.As one of the leading manufacturers of Portable Laser Welding Machines, we have been providing innovative and high-quality solutions to our clients for over a decade. Our machines are designed and manufactured using cutting-edge technology and the highest quality materials. Each machine undergoes rigorous testing and quality control checks to ensure that it meets the highest industry standards.We offer a range of portable laser welding machines to cater to the different needs of our customers. Our machines are designed to be user-friendly and offer ease of operation. Whether you need to weld small components or large structures, our machines can handle any task with precision and efficiency.Our machines are also highly customizable, and we offer a range of accessories and add-ons to enhance their functionality. From laser probes and rotating chucks to automatic wire feeders and tracing systems, we have a range of options to suit your specific welding needs.In conclusion, the Portable Laser Welding Machine is a revolutionary tool that offers several benefits over traditional welding methods. With its precision, efficiency, cost-effectiveness and versatility, it has become an indispensable tool in several industries, including construction, automotive, aerospace, and medical. As one of the leading manufacturers of portable laser welding machines, we are committed to providing our customers with high-quality and innovative welding solutions to meet their needs.

High-Powered 40w Co2 Laser Cutting System Now Available for Purchase

40W Co2 Laser Marking Machine: A Rising Star in the IndustryIn recent years, the demand for high-quality and efficient laser marking machines has been on the rise. As more and more industries realize the benefits of utilizing laser technology for marking and engraving, the market has witnessed a significant growth in the variety and capabilities of laser marking machines. One such machine that has been gaining attention in the industry is the 40W Co2 laser marking machine, which has been making waves for its precision, speed, and versatility.The 40W Co2 laser marking machine is a cutting-edge piece of equipment that utilizes a CO2 laser to mark and engrave a wide range of materials, including wood, glass, plastic, leather, and metal. It is equipped with advanced laser technology that allows for high-speed and high-precision marking, making it ideal for a variety of industrial applications. With its compact design and user-friendly interface, the 40W Co2 laser marking machine is suitable for both small-scale businesses and large manufacturing operations.One of the key players in the industry that has been making a name for itself in the manufacturing and distribution of the 40W Co2 laser marking machine is {}. With a strong focus on innovation and customer satisfaction, {} has established itself as a leading provider of laser marking and engraving solutions. The company is committed to delivering high-quality and reliable machinery that meets the evolving needs of the market.{} prides itself on the performance and capabilities of the 40W Co2 laser marking machine, highlighting its ability to deliver precise and permanent marks with minimal maintenance. The machine is designed to offer consistent performance and high-efficiency, enabling businesses to streamline their marking and engraving processes. With a team of experienced engineers and technicians, {} provides comprehensive technical support and training to ensure that their customers can maximize the potential of the 40W Co2 laser marking machine.In addition to its superior performance, the 40W Co2 laser marking machine is also recognized for its cost-effectiveness and environmental friendliness. The machine operates with minimal energy consumption and produces minimal waste, making it a sustainable choice for businesses looking to minimize their environmental footprint. By investing in the 40W Co2 laser marking machine, businesses can benefit from long-term cost savings and contribute to a greener and cleaner production process.The versatility of the 40W Co2 laser marking machine is another factor that has contributed to its growing popularity in the industry. Whether it's marking serial numbers on metal components or engraving intricate designs on jewelry, the machine offers the flexibility to handle a wide range of marking and engraving tasks. This flexibility makes it a valuable asset for businesses operating in diverse industries, from automotive and electronics to jewelry and fashion.With the increasing demand for high-quality and efficient laser marking solutions, the 40W Co2 laser marking machine is poised to become a staple in the industry. Its ability to deliver precision, speed, and versatility, combined with the expertise and support provided by companies like {}, makes it a rising star in the world of laser marking and engraving. As businesses continue to recognize the benefits of adopting laser technology for their marking needs, the 40W Co2 laser marking machine is well-positioned to meet their demands and drive the industry forward into a new era of innovation and efficiency.

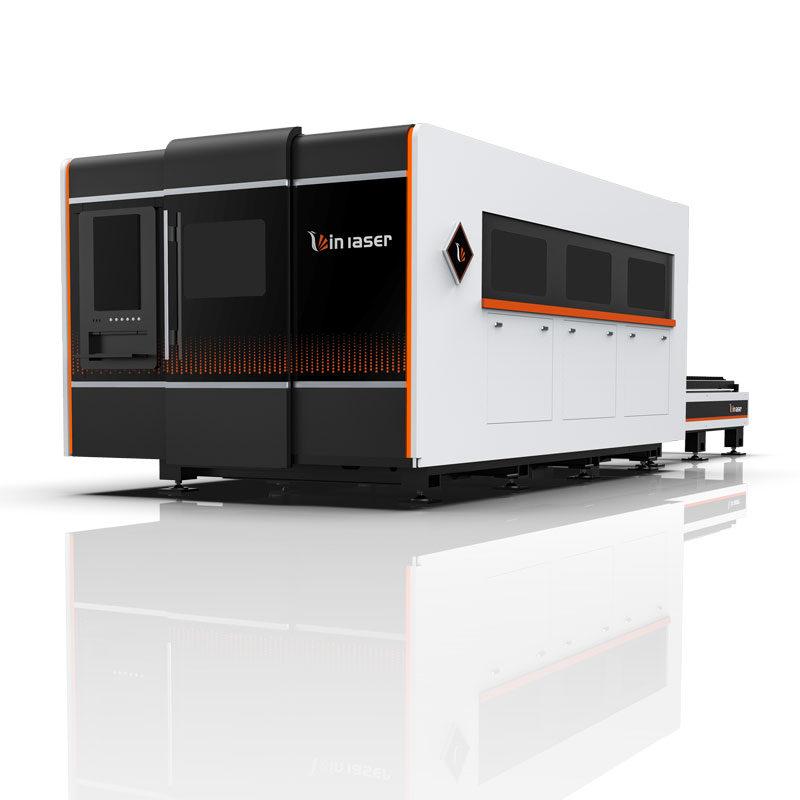

Advanced Laser Cutting Machinery for Precision Cutting

The latest innovation in laser cutting machinery has been unveiled by the industry leader in manufacturing technology, [Company Name]. This cutting-edge equipment is set to revolutionize the manufacturing and fabrication industries with its precision, speed, and efficiency.The new laser cutting machinery features advanced laser technology that allows for incredibly precise cutting of a wide range of materials, including metal, plastic, wood, and more. The high-powered laser beam ensures clean and accurate cuts, reducing the need for further processing and finishing.With the ability to cut intricate designs and patterns with ease, this machinery opens up a world of possibilities for manufacturers and fabricators. Whether it's creating custom metal parts, intricate signage, or detailed architectural elements, the new laser cutting machinery offers unparalleled versatility and precision.One of the key features of the new machinery is its high-speed cutting capabilities. With rapid cutting speeds, manufacturers can significantly increase their production output without sacrificing quality. This is especially beneficial for companies working with tight deadlines and high-demand projects.In addition to its precision and speed, the new laser cutting machinery also boasts a user-friendly interface and intuitive controls. This makes the equipment accessible to operators of all skill levels, reducing the need for extensive training and allowing for seamless integration into existing production processes.[Company Name] has a long-standing reputation for delivering cutting-edge manufacturing solutions, and this latest innovation is no exception. With a commitment to continuous improvement and technological advancement, the company has solidified its position as a leader in the industry.“We are thrilled to introduce our latest laser cutting machinery to the market,” said [Spokesperson Name], [Title] at [Company Name]. “We believe that this equipment will set a new standard for precision and efficiency in the manufacturing and fabrication industries. It's a testament to our dedication to innovation and our commitment to helping our customers succeed.”The new laser cutting machinery is already generating significant interest from manufacturers and fabricators across the globe. With its potential to streamline production processes, reduce costs, and improve overall quality, it's no surprise that this cutting-edge equipment is in high demand.In addition to the advanced technology and performance capabilities of the new machinery, [Company Name] also offers comprehensive support and service to ensure that customers get the most out of their investment. This includes training, maintenance, and ongoing technical support to keep the equipment operating at peak performance.As the manufacturing and fabrication industries continue to evolve, innovative solutions like the new laser cutting machinery from [Company Name] are essential for staying ahead of the curve. By embracing cutting-edge technology and pushing the boundaries of what's possible, manufacturers and fabricators can set themselves apart in a competitive market.With its precision, speed, versatility, and user-friendly design, the new laser cutting machinery from [Company Name] is set to revolutionize the way manufacturers and fabricators approach their production processes. This innovation is a testament to the company's ongoing commitment to pushing the boundaries of what's possible in manufacturing technology.

Top Ways to Use Laser-Cut Metal Plate for Your Projects

Laser Cut Metal Plate Offers Precision and Quality at {}{}Laser cutting technology has revolutionized the metal fabrication industry, allowing for precise, intricate designs to be cut with unparalleled accuracy and speed. {} is a leading provider of laser cut metal plate, offering a wide range of materials and thicknesses to suit the needs of various industries.With state-of-the-art laser cutting equipment and a team of skilled technicians, {} is able to produce high-quality metal plates with fine details and sharp edges. The precision of laser cutting allows for complex designs to be cut with ease, making it a preferred choice for a wide range of applications, including architectural, automotive, aerospace, and industrial projects.{} excels in providing custom solutions for clients, offering a range of metal plate materials, including stainless steel, aluminum, and titanium. The company's laser cutting capabilities extend to various thicknesses, allowing for the production of thin, delicate components as well as heavy-duty parts. Their commitment to quality ensures that each metal plate is cut to exact specifications, meeting the highest industry standards.In addition to their cutting-edge technology, {} also prides itself on its exceptional customer service. The company works closely with clients to understand their specific requirements and provide tailored solutions to meet their needs. Whether it's a one-time prototype or a large-scale production run, {} is dedicated to delivering the highest quality products in a timely manner.Furthermore, {} is committed to sustainability and environmental responsibility in its operations. The company utilizes advanced laser cutting techniques to minimize material waste and reduce energy consumption, contributing to a more sustainable manufacturing process. By investing in the latest technology and adhering to eco-friendly practices, {} ensures that its operations are as efficient and environmentally friendly as possible.As a trusted provider of laser cut metal plate, {} has earned a strong reputation for reliability and quality. The company's advanced capabilities, coupled with its dedication to customer satisfaction and environmental stewardship, set it apart as a leader in the metal fabrication industry. With a focus on precision, innovation, and service, {} continues to be a preferred choice for businesses seeking high-quality laser cut metal plate solutions.The versatility of laser cut metal plate makes it an essential component in a wide range of industries, from manufacturing and construction to artistic and decorative applications. With {}'s commitment to excellence, clients can trust that they will receive top-of-the-line products that meet their exact specifications.In conclusion, {} is a leading provider of laser cut metal plate, offering a wide range of materials, precise cutting capabilities, and exceptional customer service. From prototype development to large-scale production runs, clients can rely on {}'s expertise and commitment to quality. With a focus on sustainability and innovation, {} continues to be a trusted partner for businesses seeking reliable, high-quality metal fabrication solutions.